Light weight: weight 0.2 grams per square centimeter

Thin body: between 0.2 ~ 0.5mm thickness

Power: 80W per one square meter cold tablets available for use

Multi-shape: flexible, glow in the dark material cut, do special design

Impact resistance: can withstand high pressure up to 10 tonnes per flat feet

5 signs advantages editor

1. Super-power, short-wavelength light, no radiation, especially at night bright, eye-catching, to

attract the attention of passers-by.

2. Condenser strong, night vision distance can be very far away and attractive, penetrating fog,

strong ability of water vapor.

3. Ultra-thin, lightweight, easy to manufacture and construction, saving the project cost, manpower,

efficiency mention students.

4. Due to easy means to spread ability and advertising to maneuver.

5. With novelty and attractiveness, easy to reach ad or desired effect.

6. Cold tablets tailor-made according to customer requirements, production of various sizes, cold

tablets shape.

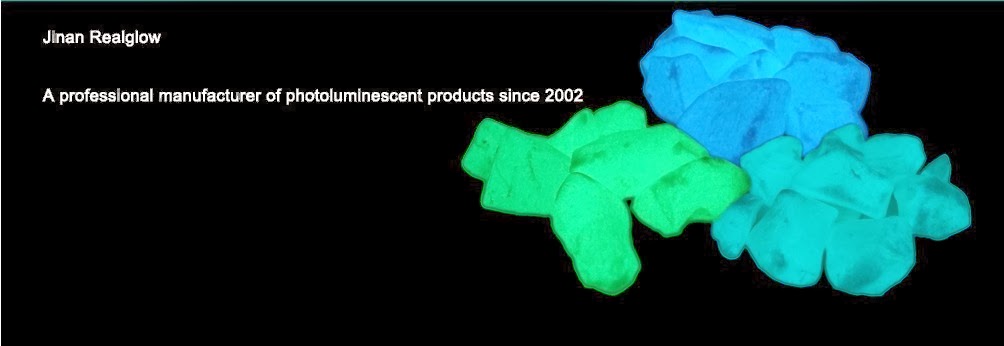

Based on the above characteristics, gravel for gardens advertising signs industry applications available from the

following direction to think about where it's cold market

1. Need to strong advertising (including: fast, permeability, weather) driven by commodities such as:

tobacco, alcohol, beverages, credit card ...... or signs such as billboards and other advertising

sales.

2. Strengthen energy-saving and safety of the aspects (can replace traditional neon tubes).

3. Liquidity marked glow in the dark stones with advertising boards, signs.