First, the main component of Epica and features luminous powder ;

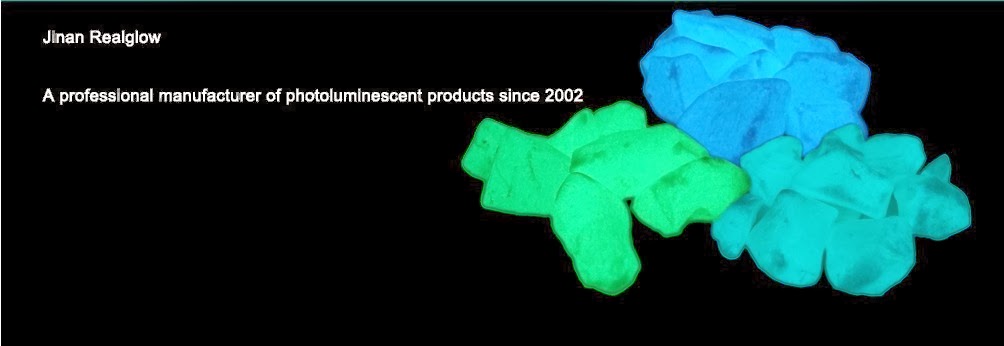

1 luminous Description Material composition mixture 4SrO.7AL2O3: Eu (Eu as rare earth elements ) .

2 main non-toxic non-radioactive luminous , no burning, no explosion, free of heavy metals or other harmful chemicals .

3 luminous with a very stable gravel for gardens chemical properties , strong adaptability to environment and extremely long service life , luminous effect can be achieved using the longest 20 years . Luminous density ρ ≈ 3.6gcm3 7. Maintain good stability at -60 ℃ -600 ℃ condition .

4 luminous luminescent time is short, high brightness, long afterglow time , rich color varieties , colors and more .

5 can be used as an additive or luminous pigment. glow in the dark dyes in a variety of transparent or translucent medium, such as paint , oil, black, plastic , rubber stamp glass , ceramics, chemical materials , to achieve self-luminous function media should exhibit good low lighting instructions and decorative landscaping effect.

photoluminescent pigment usually placed a lance material sandwich, sandwich isolated inside and outside peroxides and esters, after rubbing, two compounds react so luminous fluorescent dye

2018年6月22日星期五

2018年6月12日星期二

luminous production process

Features : Unlike the luminous phosphors , which non-radioactive , light long short but luminous efficiency , low cost , colorful. Second, the equipment: electric furnace , crucible , ball mill, drying equipment. Third, the formula : red luminous : 55 grams decorative aggregate , 40 g of magnesium sulfate , lithium phosphate, 2 g , 3 g of copper nitrate blue luminous : 63 g of calcium sulfide , sodium sulfate, 5 g , 5 g of potassium sulfate , strontium sulfate 10 g, 6 g of sodium chloride , 1 g of silver nitrate , 10 g magnesium sulfate . Purple luminous powder : 63 g calcium sulfide , magnesium sulfate 26 g , 10 g sodium sulfide , strontium nitrate 1 g . Green luminous powder : 55 g calcium sulfide , potassium sulfide 1 g , 10 g sodium sulfide , barium nitrate 12 g , 13 g of indium nitrate . Luminous yellow : barium sulfide 55 g , 40 g magnesium sulfate , aluminum sulfide 2 g , 3 g of potassium nitrate . Fourth, Crafts: after with a good raw material, the temperature on the crucible furnace heating , raw material in the pot , glow in the dark stone, mix the raw materials directly on the burning furnace , the temperature is 133 degrees , burning 50 minutes after hand -colored pick insufficiency impurities, and then placed in the cooked raw mill ground into fine powder and then soaked in water for precipitation to remove water, the sink in the powder can be placed in the drying oven . Fifth, use : put a colorless transparent plexiglass Two bananas dissolved in water . After adding 72 hours to the amount of luminous paint on watches, clocks , instruments and crafts .

2018年6月6日星期三

color ink four major characteristics

Color ink Features:

1, the temperature change ( thermochromic ) water-based flexographic printing ink and water-based gravure inks thermal water-based flexographic inks for high-volume packaging production companies, for a variety of different types of flexographic printing presses, we can deploy the corresponding ink. Mainly used in cigarettes, food , beverages, pesticides and powdered paint pigments high-volume packaging printing. Thermochromic ink water-based security on tobacco packaging conform to the current proposed environmental requirements. In line with national policy -oriented , because of its beautiful and easy to detect , welcomed by many tobacco factory , but also for cigarette packaging printing companies dominate the market and lay a good foundation .

2 , solvent- solvent-based gravure ink thermochromic thermal gravure inks for high-volume packaging production companies , printing effect is good, color fast , full color . It can satisfy the plastics and tobacco packaging printing enterprises corresponding printing.

3 , thermochromic offset ink offset ink sensitive material can glow in the dark stone , but overall lighter than ordinary printing color offset printing ink colors , mainly related with the electrochromic material . Offset printing ink we develop a uniform , smooth and complex with fluorescence techniques can be used for notes , packaging, books and other security printing , which has multiple security features.

4 , silk screen printing ink type of security inks 350 mesh can be used to good effect pattern , smooth, full color, material can meet all of the above security printing requirements.

1, the temperature change ( thermochromic ) water-based flexographic printing ink and water-based gravure inks thermal water-based flexographic inks for high-volume packaging production companies, for a variety of different types of flexographic printing presses, we can deploy the corresponding ink. Mainly used in cigarettes, food , beverages, pesticides and powdered paint pigments high-volume packaging printing. Thermochromic ink water-based security on tobacco packaging conform to the current proposed environmental requirements. In line with national policy -oriented , because of its beautiful and easy to detect , welcomed by many tobacco factory , but also for cigarette packaging printing companies dominate the market and lay a good foundation .

2 , solvent- solvent-based gravure ink thermochromic thermal gravure inks for high-volume packaging production companies , printing effect is good, color fast , full color . It can satisfy the plastics and tobacco packaging printing enterprises corresponding printing.

3 , thermochromic offset ink offset ink sensitive material can glow in the dark stone , but overall lighter than ordinary printing color offset printing ink colors , mainly related with the electrochromic material . Offset printing ink we develop a uniform , smooth and complex with fluorescence techniques can be used for notes , packaging, books and other security printing , which has multiple security features.

4 , silk screen printing ink type of security inks 350 mesh can be used to good effect pattern , smooth, full color, material can meet all of the above security printing requirements.

订阅:

博文 (Atom)